Celebrating over 50 years!

DIFFERENCES BETWEEN POLYETHYLENE AND POLYURETHANE PLASTIC TUBING

DIFFERENCES BETWEEN POLYETHYLENE AND POLYURETHANE PLASTIC TUBING

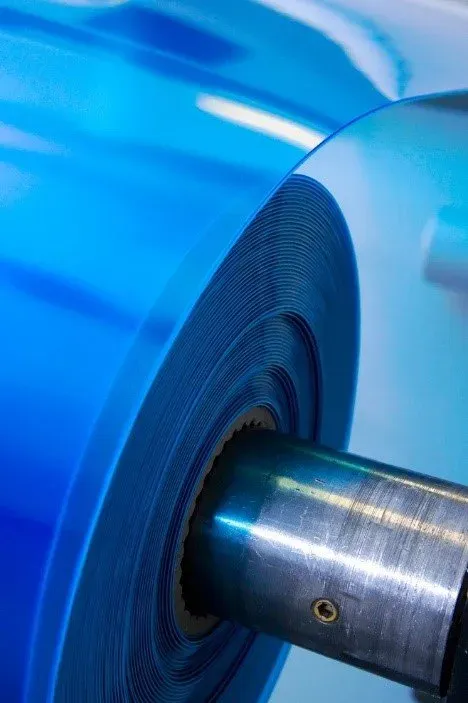

Plastic tubing is versatile and used in various applications. You'll find it in pneumatic tubing, mailing tubes, banking data carriers, farming equipment, liquid transportation, automotive parts, medical tubing, and peristaltic pumps, among other places.

Examples of plastic tubing include polyethylene, polyurethane, acrylic, polyvinyl chloride, chlorinated PVC, fiberglass, nylon, polycarbonate, polystyrene, silicone, polypropylene, and ethyl vinyl acetate. Polyethylene and polyurethane are two of the most popular types of plastic tubing.

Polyethylene and polyurethane share many similarities but also carry subtle differences worth noting. Here's an overview of the main differences between the two plastic tubing options.

What Is Polyethylene Tubing?

Polyethylene is flexible and highly durable lightweight tubing that is safe for various applications. Polyethylene is also the most common plastic worldwide and is also known as PE or Poly Tubing.

The tubing is excellent for applications that need moisture resistance and offers resilience against cracks and punctures. Most plastic bottles and corrosion-resistant pipes use polyethylene. The tubing blends well with the surroundings and provides a clean look.

You'll find many polyethylene benefits and uses. Below are some popular applications that benefit from the versatility of polyethylene tubing:

- Airlines

- Wire jacketing

- Chemical lines

- Food and beverage

- Fluid lines

- Hospital and lab applications and more.

What Is Polyurethane Tubing?

Polyurethane is another popular plastic found in many products, such as car parts, insulation, hoses, etc. Unlike polyethylene, polyurethane can be stiff or flexible and is known for its impeccable stretching properties.

Polyurethane is the go-to option if you need improved flexibility, heat resistance, and products to withstand harsh conditions. It dates back to World War II when it was an alternative to rubber. However, polyurethane is more durable than rubber.

Here are some popular applications of polyurethane tubing:

- Welding gas tubes

- Fluid lines

- Outdoor hoses

- Robotics and industrial applications

- Waste plumbing tubes and more.

What Are the Key Differences?

Polyethylene and polyurethane have many differences in terms of structure, the material used, manufacturing process, chemical composition, and applications. Below are the key distinctions:

- Production. Polyethylene tubing is an injection-molded thermoplastic resin. On the other hand, polyurethane tubing is from thermosets molded through cast and RIM (reaction injection molded) processes.

- Recycling. Manufacturers can melt, reform, and recycle polyethylene with ease. Conversely, once the polyurethane cures, the result is permanent and can't be undone.

- Hardness. Polyethylene achieves limited durometers, while polyurethane offers a wide range of durometers to select from.

- Temperature. Polyurethane offers high heat resistance of -80 to 300 degrees Fahrenheit. Polyethylene won't resist heat above 150 degrees Fahrenheit.

- Bonding. Polyethylene is difficult to bond to other subcomponents. Conversely, polyurethane bonds to various materials and is often combined with PVC.

- Forms. Polyethylene is available in solid and foam only, while polyurethane is custom formulated to the design needs.

- Recycling. Since polyethylene is a thermoplastic, manufacturers can melt old, used, and finished products and reuse them to make other moldings. Polyurethane thermosets cannot be recycled.

- ESD. Polyethylene requires carbon black to reduce and discharge electrostatic buildup. On the other hand, polyurethane dissipates electrostatic buildup without carbon black.

Which Option Is the Best?

Polyurethane and polyethylene have various other differences, including distinct applications. Polyurethane tubing generally performs better under harsh conditions and will maintain form.

Polyethylene will lose form under temperatures above 150 degrees Fahrenheit. As such, you need custom solutions for the application. Polyethylene suits low-temperature and low-pressure applications.

Seiler Plastics has more than 40 years of experience in the plastic tubing industry and focuses on custom solutions. You can speak to an expert for professional insights about tubing selection. Contact us today at Seiler Plastics to find out more and the best options for your needs.

Seiler Plastics

Address

Corporate Office

9750 Reavis Park Drive

St. Louis, MO 63123

North Location

1277 Ambassador Blvd.

St. Louis, MO 63132