5 REASONS TO CHOOSE HDPE PIPES FOR IRRIGATION SYSTEMS

5 REASONS TO CHOOSE HDPE PIPES FOR IRRIGATION SYSTEMS

Any irrigation system, from a small lawn sprinkler network to an extensive golf course irrigation system, is only as effective and reliable as the piping it uses to transport water. In the past, most irrigation systems on commercial or residential properties had piping and tubing of PVC plastic, galvanized steel, or aluminum.

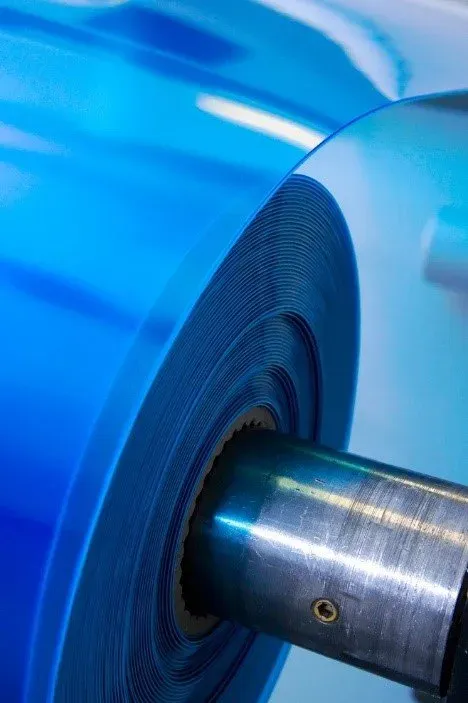

However, many modern irrigation systems rely on high-density polyethylene (or HDPE) piping — and for good reason. This remarkable plastic has a number of unique properties that make it an ideal choice for carrying water through irrigation systems. Discover five reasons to choose HDPE piping for any irrigation project.

1. Reduced Leakage

Lengths of irrigation piping of PVC or aluminum must join with separate connectors, such as bushings and couplings, which attach to the piping with built-in threading or sealant tapes. However, these connectors are prone to leakage and can allow gallons of water to escape the system over the course of an average season.

HDPE pipes HDPE connect to fittings or other pipes using a different process, known as butt-fusion. This process involves heating the ends of the pipes that will be attached and fusing the pipes together while their ends are still in a semi-liquid state. The joined pipes are then allowed to cool and set, creating a completely watertight seal.

This unique pipe joining process allows irrigation installers to create long, continuous lengths of HDPE piping that do not rely on leak-prone pipe connectors. Separate connectors will still be necessary at certain points in the system, but minimizing the number of connectors in the system will make the completed irrigation system significantly more leak-resistant.

2. Superior Flexibility

HDPE piping is more flexible than most other types of piping in irrigation systems, and HDPE pipes can bend to relatively severe angles without suffering damage. This allows HDPE pipes to go around immovable obstacles, such as boulders or subterranean utility lines, without relying on elbow connectors or other fittings.

3. Longer Lifespan

The piping in irrigation systems can also be damaged by rapid increases and decreases in internal water pressure, which occur whenever the system's sprinklers turn on or off. Over time, the physical stresses from these sudden pressure changes can weaken and deform the piping, reducing the amount of water pressure it can handle without leaking or splitting.

Because HDPE piping is so flexible, it is less vulnerable to these stresses than PVC and other commonly used piping materials and can expand and contract in response to pressure changes without any significant weakening or deformation. As a result, HDPE piping has a longer usable lifespan than most other piping choices and can last for over 50 years with proper maintenance.

4. Higher Freeze Resistance

The winter months can wreak havoc on many irrigation systems. When outside temperatures drop below freezing, any water inside the system's pipes will freeze and expand, which places the pipe walls under an enormous amount of stress. Freezing water can rapidly damage irrigation pipes of metal or non-flexible plastics.

HDPE does not become brittle at subzero temperatures, and its innate flexibility allows it to expand to accommodate freezing water. Draining an irrigation system with HDPE pipes is still highly recommended, but if any water does remain in the system when the temperature drops, the system is less likely to suffer catastrophic damage.

5. Environmentally Friendly

HDPE piping is also a relatively eco-friendly choice for an irrigation system. The material itself is 100% recyclable, even after long years of use, and can be melted down and reformed to create new HDPE products. It also does not release toxic vapors or other compounds at high temperatures, unlike some other types of plastic.

These are just some of the reasons why irrigation specialists rely more and more on HDPE piping and tubing. If you have any more questions about suitable applications for HDPE tubing, contact the plastic experts at Seiler Plastics.