Celebrating over 50 years!

BIOPLASTICS: A GREAT OPTION FOR YOUR NEXT MANUFACTURING PROJECT

BIOPLASTICS: A GREAT OPTION FOR YOUR NEXT MANUFACTURING PROJECT

Modern-day consumers appreciate companies whose operations reflect their values. As the vast majority of the global population warms up to green living, biodegradable raw material could easily become the future of manufacturing.

A company that adopts an eco-friendly culture is far more likely to attract and retain customers. Thankfully, biodegradable plastic and other environmentally friendly materials go way beyond a solid public image.

There's a lot more to gain from using such plastics, both in the practical and economic sense.

The Key Manufacturing Differences

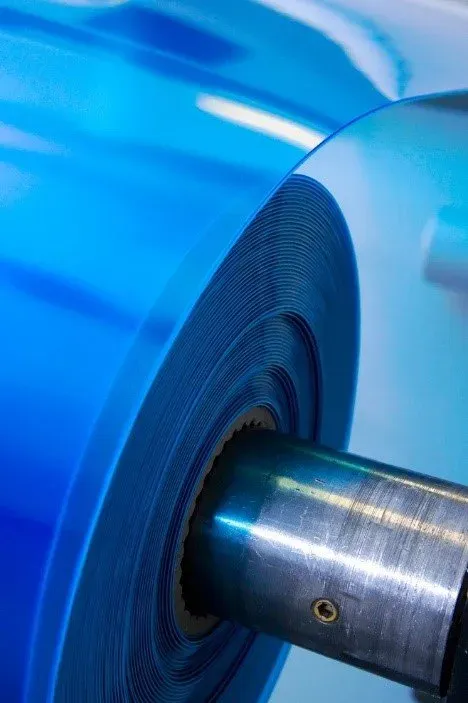

Generally, both traditional and biodegradable plastics utilize the same industrial processing techniques. However, the processing raw materials for the two types of plastics are different.

Normal plastics' raw materials are petroleum-based substances. Eco-friendly plastics are made from material that is easier to break down. The material used doesn't have destructive components such as bisphenol A and is, therefore, less toxic.

Typically, bioplastics can be divided into the following categories.

- Biodegradable plastic. These plastics can break down to form water and carbon dioxide. Biodegradable plastics are often made using certain additives to ensure faster breakdown

- Compostable plastic. Certain microorganisms can break down these plastics inside a compost site to form water, carbon dioxide, and other inorganic matter. Usually, compostable plastics can disintegrate fully without leaving any toxic substances as residue. They are made from materials such as cellulose and corn.

Typically, bioplastics break down faster if there's moisture present. Other times, UV light from the sun may be enough to initiate the breakdown process.

What Are the Added Benefits of Using Bioplastics?

Compared to traditional plastics, bioplastics have some concrete advantages that you may want to consider.

Smaller Carbon Footprint

Biodegradable polymers typically have lower carbon emissions compared to traditional plastics during the manufacturing process. Excessive carbon emissions add to the greenhouse effect, with a bad impact on the environment. Most of the compost processing materials are plant-based hence the lower emissions.

To better understand this magnitude, processing bioplastics creates about 30 percent less carbon emissions than normal plastics. If your company values include environmental protection, using bioplastics in your manufacturing projects can help achieve that goal.

Lower Energy Demands

You may require lesser energy during the manufacturing phase when you use biodegradable plastic. However, more energy from fossil fuels is needed when working with traditional plastics. If you use traditional plastics, you may have more heating demands to turn the plastic molecules into what you need.

Because your energy requirements are much lower, environmental pollution remains at a minimum. Less energy requirements may also translate into lower expenses. You can therefore channel your fuel resources to other needs such as heating and transport.

Easily Recyclable

Most non-biodegradable plastics contain toxic elements that make repurposing and recycling a difficult task. Sometimes, harmful chemicals can leak and become a constant threat after initial use.

Thankfully, bioplastic material is less toxic since it's made from naturally occurring materials. These bioplastics have oils that make things easier during the recycling and repurposing processes. The material is malleable enough to easily form new shapes. Moreover, you can recycle and repurpose these plastics as much as you want within their life cycle.

Oftentimes, recycled plastic integrates well with most of the manufacturing equipment, allowing for easier adoption. Additionally, bioplastics can help you turn your recycling vision into reality, therefore improving your brand image.

Going green is a strategy that can help you lower mass production costs while still protecting the environment. You can do your part by switching from your regular plastic raw material to more eco-friendly options. A reliable custom plastic extruder like Seiler Plastics can help with fabricating high-quality, fully biodegradable plastic to fit your needs.

Seiler Plastics

Address

Corporate Office

9750 Reavis Park Drive

St. Louis, MO 63123

North Location

1277 Ambassador Blvd.

St. Louis, MO 63132