Celebrating over 50 years!

6 COMMON USES FOR PLASTIC SHEETS

6 COMMON USES FOR PLASTIC SHEETS

Nearly every industry utilizes plastic. From consumer products to large-scale industrial projects, plastic has a wide range of applications due to its versatility, cost-effectiveness, and durability. Below are six ways this common material is used in one of its many forms: plastic sheets.

1. Insulation

In many construction projects, plastic sheets are ideal insulators. Plastic sheets are durable, making them a choice option for protection against extreme weather conditions. When placed between walls, plastic sheeting insulates and helps to regulate temperature in both very hot and very cold weather. Plastic sheets are also water-resistant, making them an ideal choice for many insulation applications.

Plastic sheets are useful for container insulation, too. Chemical containers benefit from plastic sheeting because of its resistance to corrosion. Iceboxes lined with plastic sheets help to keep products at optimal temperatures by preventing significant moisture and temperature changes from affecting or spoiling their contents.

2. Shelter

Greenhouses, emergency shelters, and camping structures are all ways plastic sheeting can be used to build shelters and temporary buildings. In times of emergency, public and private institutions have employed plastic sheets in erecting crisis shelters. Roofing that utilizes plastic sheets can safeguard shelters from torrential downpours and excessive heat from the sun's rays.

Plastic sheets also house more than people. Sheeting can protect large containers, machines, or stores of natural resources from the elements. Through dust, storms, temperature changes, and elemental impact, plastic sheets offer a strong and protective shield for other, more vulnerable materials.

3. Construction

When in need of lightweight, reliable material, construction project teams often turn to plastic sheets. Because of the range of options, plastic sheeting can serve as protective, foundational, or even decorative elements of building construction. Plastic sheets can be easily customized to suit construction projects by tailoring size, thickness, and thermoforming to the project's specific needs and dimensions.

Formable plastics can take just about any shape, including textured sheets, bars, vents, furniture, canopies, and finishing materials. The variety of weights and thickness of plastic sheets provide nearly unlimited options, and plastic sheets have become more and more common in modern architectural elements.

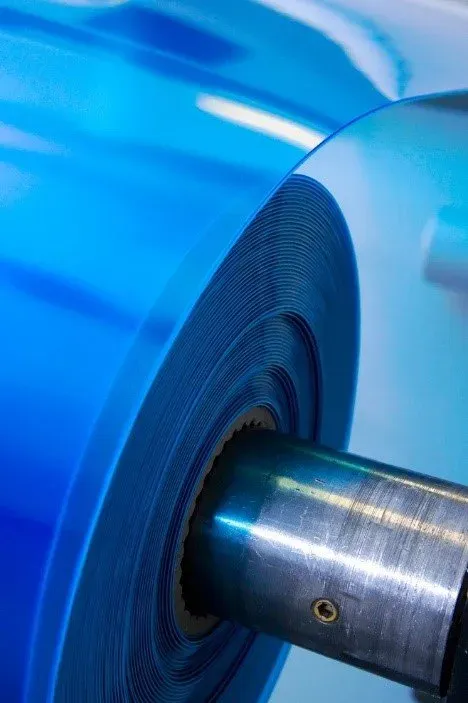

4. Industry

Since plastic sheets can be manufactured in various thicknesses, shapes, and sizes, industrial companies have many uses for them. Unlike other materials, plastic sheets are moisture-resistant and aren't as susceptible to degradation processes like rust or corrosion.

Plastic sheeting helps to form machine parts, shipping or storage containers, boxes, and packaging. Many fields utilize plastic sheets in their market, including the food, medical, cosmetic, and home improvement industries.

5. Waterproofing

When you need to contain water or prevent it from reaching other areas, plastic sheets are an excellent material candidate because of their resistance to moisture. Plastic sheeting is an economical option for large scale applications especially. Liners for ponds, pools, and canals are all typically from plastic sheets, especially high-density polyethylene.

As well as landscaping or water body application, plastic sheets can create a temporary or permanent water seal for containers, windows, and irrigation systems. Plastic sheets can even efficiently collect and store water runoff or rainwater.

6. Recreation

Many of the recreational vehicles and equipment once formed from wood and metal now utilize plastic for their construction. Thermoformed plastic sheets have become sleds, ATVs, boats, remote control vehicles, and playground or exercise equipment.

Though they have the typical practical and durable qualities, plastic sheeting comes in a wide variety of colors. Plastic sheets won't chip, rust, or warp over time like other materials, making them the perfect choice for recreational equipment.

These are just a few of many applications, but the possibilities with plastic sheets are endless. To get started on your next project or to explore the many plastic sheet options, contact Seiler Plastics to speak with a plastic expert.

Seiler Plastics

Address

Corporate Office

9750 Reavis Park Drive

St. Louis, MO 63123

North Location

1277 Ambassador Blvd.

St. Louis, MO 63132