Celebrating over 50 years!

FROM PELLETS TO PIPING: HOW THE EXTRUSION PROCESS WORKS

FROM PELLETS TO PIPING: HOW THE EXTRUSION PROCESS WORKS

Plastic extrusion is a process by which plastic particles, in the form of pellets, dust, or a solid mass, are transformed into sheets of plastic for specific uses. These forms of plastic can then turn into a variety of products, from molds for parts to tubes for indoor or outdoor piping.

This process is extremely common, especially when you consider how many common plastic goods are. How does this transformation take place, though? Learn more about plastic extruding here.

Step One: Load the Plastic

Whatever form the plastic comes in initially, it goes into a hopper (a container for bulk material) at one end of the extruder. The raw material will have to go through a tube that will have one or two revolving screws within it — this is the part technically referred to as the extruder or extruder screw.

Step Two: Extrusion

As the plastic goes through the extruder, the screws turn and generate energy. A single screw extruder, the most widely used and versatile, obviously can only turn one way, while a twin screw extruder has a couple of options. Twin screw extruders can be co-rotating, meaning that they both rotate the same direction. The other option is counter-rotating, meaning that the two screws rotate in opposite directions.

Whatever way the screws work together, they generate energy that, combined with heavy pressure, transfers to the plastic pieces as heat. The heat melts down the plastic into a liquid, the right state for the next part of the process.

Step Three: Shaping

The temperature within the extruder screw is regulated carefully, depending on the desired material outcome. The plastic exits the extruder into what's called a die, which shapes the molten plastic into the desired form. A screen is in place to keep out any contaminants in the melted plastic, and a breaker plate keeps the screen intact.

The die is carefully designed and often custom-made to specific requirements. The die must maintain even flow to all the nuances of the form so that it comes out correctly and doesn't leave any room for warps, stresses, or imperfections that could easily break in the final product.

Step Four: Cooling

The formed plastic now has to cool down and solidify, and, usually, production requires it to cool quickly. The die will either travel through a water bath, utilize cooling rolls, or use cold air to harden the plastic within. Plastic resists rapid cooling due to its insulating nature, but these techniques help the process along.

Step Five: Packing It Up

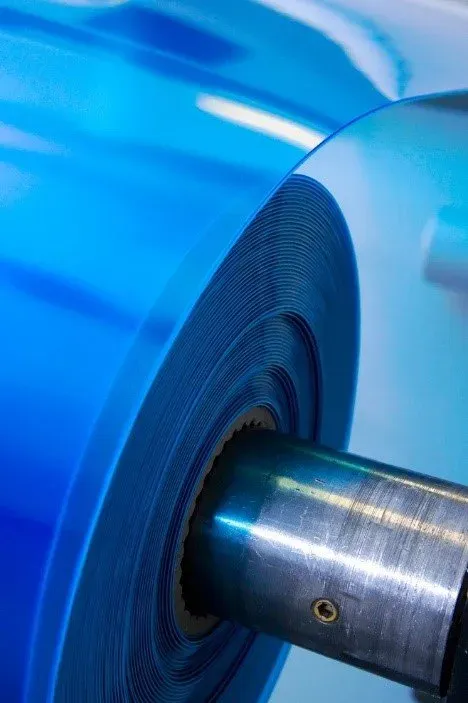

Depending on what the customer has in mind for the plastic, the extruding company prepares the material in one of several ways. For long, thin, and flexible sheets of plastic, the company may spool the plastic into a large roll. For thicker, harder, and smaller pieces, the plastic may be cut into the requested size and carefully stored in a box until it reaches the final destination.

Step Six: Ready to Use

As previously mentioned, extruded plastic is useful in a variety of ways. Plastic tubes are one popular product, which has many multifaceted purposes. Vinyl fences are often made with extruded plastic, as are a lot of outdoor furniture and decking. Vinyl siding for homes is often extruded, and many windshield wipers and auto trim pieces are the same way.

Plastic extrusion is a convenient and versatile process that can make all sorts of different products for both indoor and outdoor use.

Now that you understand the work that goes into this process, you need to find a reliable extrusion company to help you. Contact Seiler Plastics Corporation today for all of your plastic extrusion needs.

Seiler Plastics

Address

Corporate Office

9750 Reavis Park Drive

St. Louis, MO 63123

North Location

1277 Ambassador Blvd.

St. Louis, MO 63132