Celebrating over 50 years!

4 PLASTIC CONSIDERATIONS FOR NEW PRODUCT LAUNCHES

4 PLASTIC CONSIDERATIONS FOR NEW PRODUCT LAUNCHES

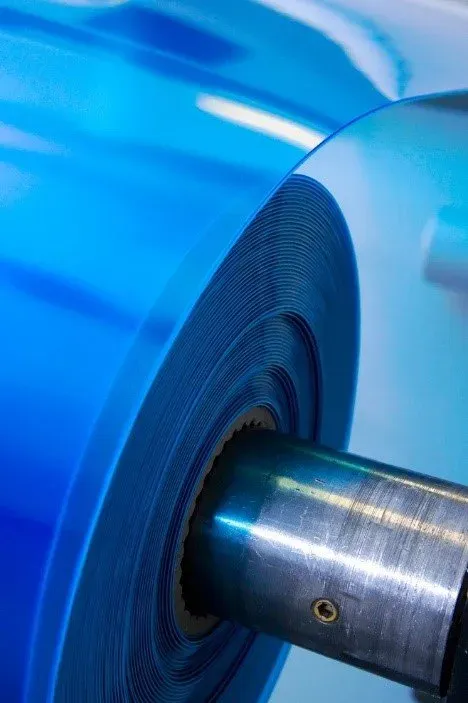

Plastic is often one of the main material types for new product launches. The material is durable and flexible and works for all kinds of applications. Plastic comes in many shapes and forms, so when you choose plastics for a product, you have a lot of things to consider.

Learn about four main considerations and how your choices can make an impact on your final product design.

1. Pantone Color Options

One of the main advantages of selecting a plastic is choosing specific colors. Many plastic manufacturing companies will use Pantone color codes to select the perfect shade of color for the plastic. Pantone colors are color-coded so you can select an exact color for your project. You do not need to give a name or guess on a specific shade.

Since computer monitors and screens often feature slight changes in the color calibration, you can request a box of Pantone plastics selector chips. The box comes with the exact shades and codes so you can manually go through the colors and find the best finish for your plastic.

A plastic manufacturing plant will include the colors in a special plastic mixing machine that will automatically mix and blend to achieve the shade you are looking for. During a trial prototype run, you may select multiple colors to see how your finished product looks in various shades.

2. Opaque or Clear Plastics

Some plastics have features that allow clear options. If your product involves a liquid or needs clear elements, then you want to seek out plastics with those features. For example, a plastic like polyethylene terephthalate is often used for plastic water bottles. If you seek out a clear plastic with stronger properties, then consider polycarbonate.

The opaque options vary as well. You may choose a plastic finish with a cloudy look or one that is completely clear. You can also choose a plastic that is completely opaque so you have a solid design that may feature a little extra thickness.

3. Indoor or Outdoor Use

Every plastic has different weather resistance. If your product is primarily for outdoor use, then you want to select a plastic that handles moisture and extreme temperatures. One of the more ideal options for outdoor use is cellulose acetate butyrate. Cellulose acetate butyrate is useful in many industries, including home exterior applications.

If your product is primarily for indoor use, then you have more flexibility in the plastics you choose. For example, acrylonitrile butadiene styrene sheets may not be as weather-resistant as cellulose acetate butyrate but do have the flexibility to form into multiple shapes and sizes for your product needs.

4. Price and Budget

As you select a plastic for your project, you want to ensure the plastic fits within your price range. Choosing a more expensive plastic can increase your wholesale product price and may result in fewer sales if the price points become too high. As you plan out your project needs, work with a plastic manufacturing company on a detailed estimate.

The estimate can include the whole prices for different plastic materials and extra options you seek. With the numbers, you can break down individual costs and how much money you need to put in to each specific product. From there, you can break down your plastic options and choose the most cost-effective option that also works with your product creation.

The plastic budget will also help you budget out other material needs. Your product may have some metal elements you also have to budget for the final project. You may also look into discounts for bulk orders. If you have a larger order, then you may get bigger discounts and the price per unit price can come down dramatically.

For estimates and more product information, contact us at Seiler Plastics. We will help you plan out your product from start to finish. Our expert engineers will also help answer any questions you have along the way.

Seiler Plastics

Address

Corporate Office

9750 Reavis Park Drive

St. Louis, MO 63123

North Location

1277 Ambassador Blvd.

St. Louis, MO 63132