Celebrating over 50 years!

5 USES OF PLASTIC TUBING

5 USES OF PLASTIC TUBING

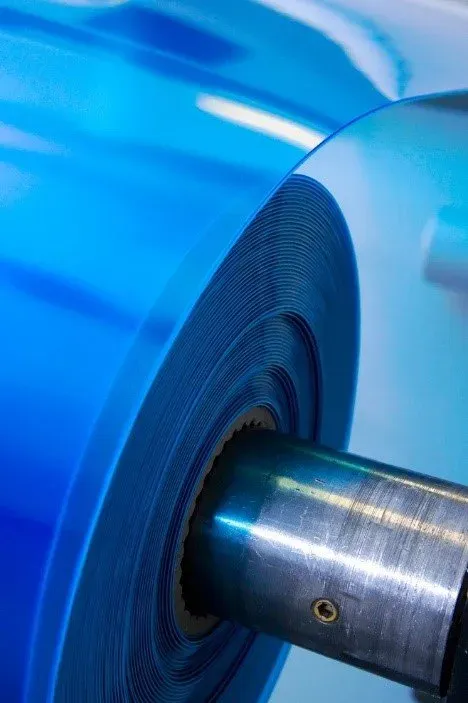

Plastic has revolutionized almost every industry, even if you don't notice it. If you've ever wondered where plastic is being used, check out these five common uses for plastic tubing.

1. Medical Supplies

The medical field moves quickly, so it's no surprise that hospitals turn to plastic tubing for a durable and easy-to-use option for medical supplies and equipment. Plastic tubing is resistant to bumps and permeation, making it a great choice for supplies like:

• Catheters

• IVs

• Drainage equipment

• Feeding tubes

You'll also find them in instruments used to diagnose patients and transfer fluids.

The durability of plastic keeps tubing contents contained and protects patients and hospital staff from contamination or spills. The resistance to permeation ensures that the liquid that enters a patient's body is pure and untouched.

2. Irrigation

Plants rely on rain as well as irrigation to grow strong. Irrigation can take the form of underground water pipes, sprinkler systems, or residential hoses. And plastic tubing is often the choice for each one of them.

Agricultural

Farms use underground pipes to maintain a supply of water to keep their crops healthy and growing. And while steel and brass are common choice, plastic offers the flexibility and durability that the other materials often lack. When farmers choose plastic tubing, they don't have to worry about driving heavy equipment over the underground tubing, as the tubing's flexibility allows the pipes to bend rather than break.

Plastic tubing is also durable, meaning it is more cost-effective than other materials.

Residential

When you water your lawn or garden, your sprinkler system or hose is made from plastic tubing that is designed to withstand common residential damages, such as pests and the elements.

3. Automotive Fluid Lines

Your car relies on a variety of fluids to run smoothly. And plastic tubing is what transfers those liquids where they need to go.

Plastic tubing can also resist temperature damage and corrosion, and it is designed to withstand the heat of a car engine, even during the heat of summer. The tubing also stays strong against the corrosion of chemicals like gasoline and transmission fluid. These qualities make it an excellent choice for the automotive industry.

4. Packaging and Shipping

As a consumer, you likely have both seen and bought plenty of items in plastic packaging, possibly even in plastic tubing. Because of plastic's durability and versatility, manufacturers, sellers, and shippers use plastic tubes to package and ship products of all kinds.

Plastic tubes can be custom made to fit even unusually shaped products as well as those that are large or small. And their durability ensures distributors that the items will be safe during transit and while waiting to be purchased.

You may notice that shipping tubes are also often made of plastic to ensure items are protected from impact damage, water damage, or particles of any kind.

5. Crafts

Of course no piece of material can get past the DIYers of the world. Dedicated to use everything around them, many crafters take advantage of old or extra pieces of plastic tubing for crafts of all kinds. And with the versatility, flexibility, and durability of plastic, there's no shortage of crafts you can make.

Many people use plastic tubing for outdoor crafts like bird feeders, tool holders, or organizational gadgets. Some create unique jewelry out of small, clear tubing and insert something colorful or textured inside to show through. You can even find plastic tubing in art and sculptures of all kinds.

As you can see, plastic tubing is a vital part of many industries, and it continues to provide new and improved uses in other industries as well. Whether you have a need for custom plastic tubing or you want to learn more about its uses, contact us at Seiler Plastics today.

Seiler Plastics

Address

Corporate Office

9750 Reavis Park Drive

St. Louis, MO 63123

North Location

1277 Ambassador Blvd.

St. Louis, MO 63132