4 BENEFITS OF CLEAR PLASTIC U CHANNEL MOLDING FOR PRODUCTS

4 BENEFITS OF CLEAR PLASTIC U CHANNEL MOLDING FOR PRODUCTS

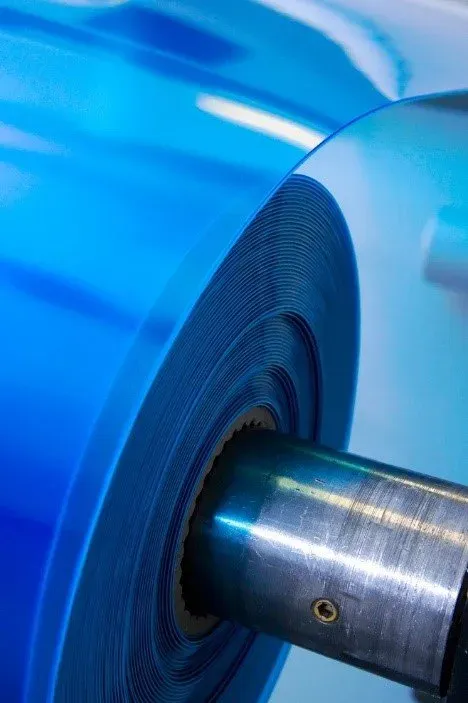

Plastic has a versatility that allows manufacturers to shape and mold the material into all kinds of designs. In the world of manufacturing, one form of plastic commonly used is the U channel. Like the name states, U channel plastic is formed into the shape of a U and intended to wrap around other materials like wood, metal, or thicker plastic.

As you work on prototype products like furniture, household goods, or accessories, one element you may want to add to the product is plastic U channel molding. The molding comes in many finishes, but you can also seek clear U channel molding with no color attributes attached. Check out some of the advantages of U channel plastic for your manufactured products.

1. PRODUCT VISUALS

One of the main benefits of clear plastic is the ability to blend in with a product. You do not need to worry about matching color tones between the plastic and the other material. The translucent properties help the colors stand out underneath and allows the plastic to blend naturally with the product design.

Order thin cut U channel plastic to help the clear plastic blend in even more. The design helps create pieces that stand out and allows product designs to look how they were intended.

2. EDGE PROTECTION

A clear plastic molding adds edge protection. You do not need to worry about chips, dents, or dings in the material the plastic wraps around. The quality of the product will remain the same and is especially helpful when products are moved around or transported.

You also do not need to worry about the plastic itself showing any damage. The clear material allows products to look new and in mint condition for the lifespan of the product.

3. GRAPHIC PROTECTION

If your product has labels, company logos, or other visual graphics, then a clear U channel mold will allow consumers to see the text easily. The plastic offers clear visuals and protection at the same time. You do not need to worry about the deterioration of stickers, labels, stamps, or painted-on elements.

The plastic can protect the graphics from dust, humidity, and human touch. The colors and designs will remain on the products for years to come, even if sticker glue or other adhesives wear off. The U channel wraps around the edges smoothly so none of the graphics get obstructed by angles or sharp curves.

Many of the plastic materials offer UV protection, so sunlight and other sources of UV light will not cause colors to fade or change over time. The advantage is much better than leaving graphics exposed to open air.

4. EXACT SIZING & EASY CUSTOMIZATION

When you plan new products with clear plastic U channels, you have a lot of options to choose from. Plastic companies can work easily with the product and create custom pieces that are cut down to exact sizes. As you work on prototypes, you have the option to order sample pieces and try out the clear plastic to see how it works.

The sizing allows you to order exact measurements that will fit around certain areas. The curve of the U shape can ensure the plastic remains secure and grips over areas like a hanging edge. You can also see how thin you want the plastic to be and how the differences in thickness impact a project.

For more information on clear plastic U channels, contact us at Seiler Plastics. We make every project to order and can create a U channel product that fits your exact needs and includes all of the benefits above. We can also manufacture any other plastic needs for prototypes or full production needs.